- #PUMP LADDER LOGIC PROGRAM DRIVER#

- #PUMP LADDER LOGIC PROGRAM MANUAL#

- #PUMP LADDER LOGIC PROGRAM SOFTWARE#

Thus, the software for these systems is very extensive and requires a combination of design documents.

#PUMP LADDER LOGIC PROGRAM MANUAL#

SCADA software involves much more than a set of engineering drawings as will be explained in subsequent chapters, the application software for a SCADA project involves spreadsheets, design documents, user reference manual material and detailed program information. And then came the issue of interconnectivity with other systems: the result was Local Area Networks (LANs) and WANs.

#PUMP LADDER LOGIC PROGRAM DRIVER#

Interconnecting the HMI and PLC equipment required more advanced methods of communication, such as networks and special driver software. PLC), the combination of these devices evolved into what is now referred to as a SCADA system. HMI) and sophisticated field controllers (i.e. As this user interface evolved, there was again a need to better organize and design the images and information being displayed to the user. Then the CRT led to Liquid Crystal Displays (LCDs), which required much less space with better resolution. First there was the Cathode Ray Tube (CRT), which was combined with a keyboard. With this added functionality, there was a need to better organize and design the software for the PLC.Īt the same time, HMI, developed from simple meters, chart recorders, and pushbutton and selector switches, into very sophisticated graphic interfaces. But as the PLC software evolved into more complex features and operations, the programming extended well beyond what could be done in an electrical wiring diagram. At first, this approach worked well, as the electrician already understood how a program should work. Traditionally, the PLC was programmed by electricians, as the ladder logic programming was designed to resemble electrical diagrams. McCrady, in Designing SCADA Application Software, 2013 1.3 Defining the Scope of SCADA Software In some PLCs, all immediate outputs do not wait for the program scan to end before setting an output. This is like a flip-flop and stays set even when the PLC is turned off. When the L is energized, this X will be toggled on, and will stay on until the U coil is energized. An input transition on will cause the output X to go on for one scan (this is also known as a one-shot relay). When power is applied (ON) the output X is activated for the left output, but turned off for the output on the right. The last instruction is the IOT (Immediate Output Terminal) that will allow outputs to be updated without having to wait for the ladder logic scan to be completed. The output can only be turned off using a U output. When an L output is energized, the output will turn on indefinitely, even whenthe output coil is deenergized. The L (latch) and U (unlatch) instructions can be used to lock outputs on. When initially energized, the OSR (one-shot relay) instruction will turn on for one scan, but then be off for all scans after, until it is turned off. This type of output is not available on all PLC types. When it is energized, the output will turn off.

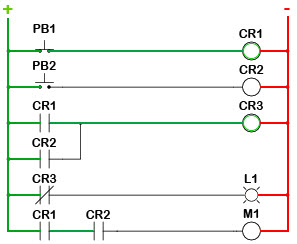

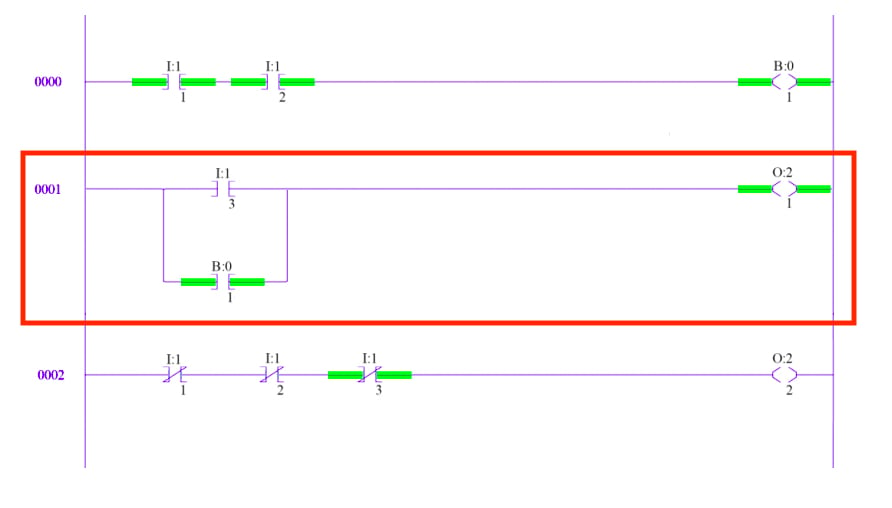

The circle with a diagonal line through it is a normally on output. The first is a normal output when energized it will turn on and energize an output. Six types of outputs are shown in Figure 7.7(c). Some will be externally connected, as may the internal memory locations in the PLC. In ladder logic, there are multiple types of outputs, but these are not consistently available on all PLCs.

Immediate inputs will take current values, but not those from the previous input scan. This allows ladder logic to examine input values more often than once every cycle. The IIT (Immediate Input Terminal) function allows inputs to be read after the input scan, while the ladder logic is being scanned. Normally closed: power flows when the input X is not open. Normally open: an active input X will close the contact and allow power to flow. The first two are normally open and closed inputs, discussed previously. Figure 7.7(b) shows the three types of inputs. PLC inputs are easily represented in ladder logic. Relay ladder logic representations: (a) a seal-in circuit (b) ladder logic inputs (c) ladder logic outputs.

0 kommentar(er)

0 kommentar(er)